Cans are projected to constantly grow over the next few years. Manufacturers need greater performance to match the overall rising demand, while guaranteeing absolute food safety, minimizing Total Cost of Ownership (TCO) and preparing for future production needs.

A broader number of SKUs and numerous can sizes on the market call for higher flexibility, requiring swift changes between still and carbonated, as well as hot-, ambient- and cold-filled beverages.

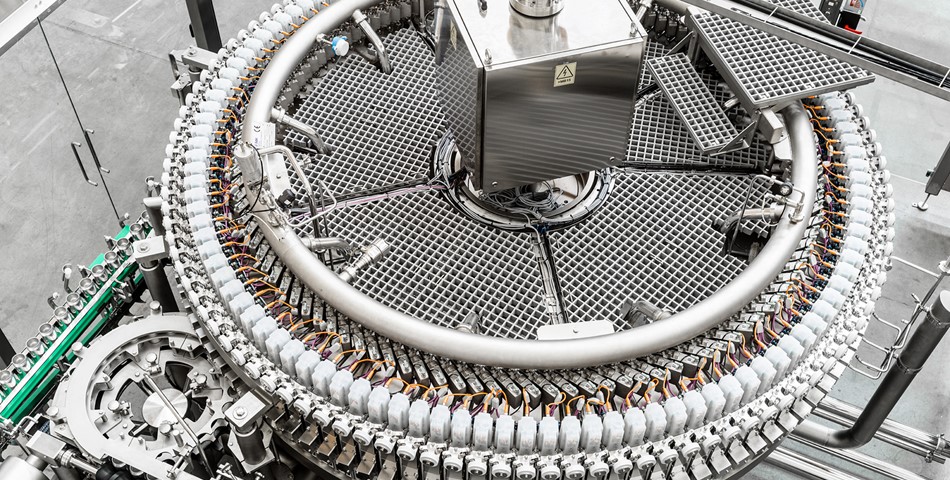

The answer to all these challenges is the new Sidel filler, EvoFILL Can. Addressing top hygienic requirements, EvoFILL Can’s “no base” design, which as a whole is very accessible, ensures an overall easy cleaning and no residual of product in the filling environment.

The solution’s improved CO2 pre-flushing system results in utmost food safety, as there is no residue and a cleaner zone. Consuming less CO2 in total, this feature improves beverage quality and leads to greater performance.

For beer producers, this means lower O2 pick-up, down to 30 ppb, nonetheless saving resources. With a single or double can infeed available EvoFILL Can allows for a flexible upstream line configuration. With the solution operating at high speeds of over 130.000 cans per hour (cph), the double infeed allows for the best can quality as containers suffer much less stress and no damages.

As hygiene is a key component for the overall product quality, Sidel’s engineers developed a new drive system, enabled by servomotors. It requires no mechanical transmission between the filler and the seamer, thus eliminating any need for lubrication and any moving parts in the filling area.

The new drive system also leads to better accessibility, which speaks to the greater ergonomics of the solution, and minimizes TCO through savings on maintenance and energy. Additionally, because no water is needed for the lubrication of rollers, it cannot drip down during the filling process nor remain inside the filling environment, potentially contaminating the product.

For utmost hygiene, the design of the solution has been optimized further: it now includes fully cleanable handling parts with reduced top surfaces. Therefore, cleaning is more effective and there is no risk of chemical agent or water residual.