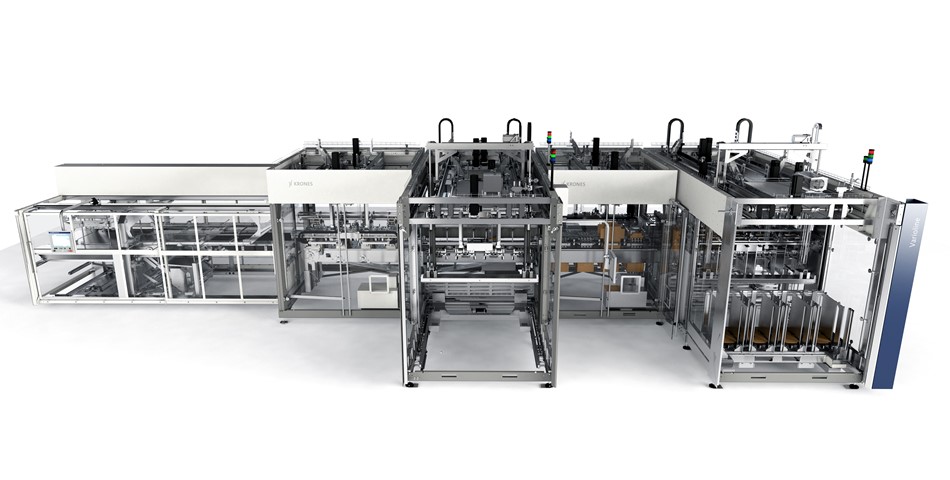

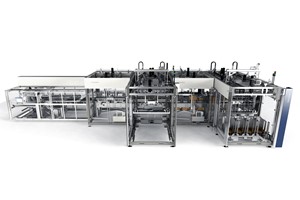

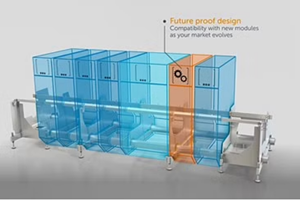

The Varioline packaging system has proved highly successful in establishing itself within the beverage industry. As evidenced by more than 30 machines commissioned within a period of just two years. There are good reasons for this. For the beverages industry, flexibility in end-of-the-line packaging is an increasingly important consideration. Often individual containers have to be first placed in multipacks, and these then packed in an appropriate sales or outer package. Since both the multipacks and the end-of-the-line packages are subject to changing consumption trends and will vary for different target groups, consumption occasions or export nations, maximized flexibility is imperative. By developing the Varioline as a flexible solution, Krones has found the right answer for this job profile. The basic idea involved is that a single machine replaces up to six conventional individual machines linked by conveyors. With the Varioline combination conjuror, packaging processes involving up to three stages can be handled by just a single machine. The logical consequence is space savings, reduced maintenance work, and fewer operators. The modularized Varioline kit consists of three modules, which can be combined to form a customized packaging system. These three units, the cartoning, feed and basic modules, feature an identical basic construction, to create a modularized design concept that ensures flexibility for the future. The machine can handle up to 52,000 containers per hour.